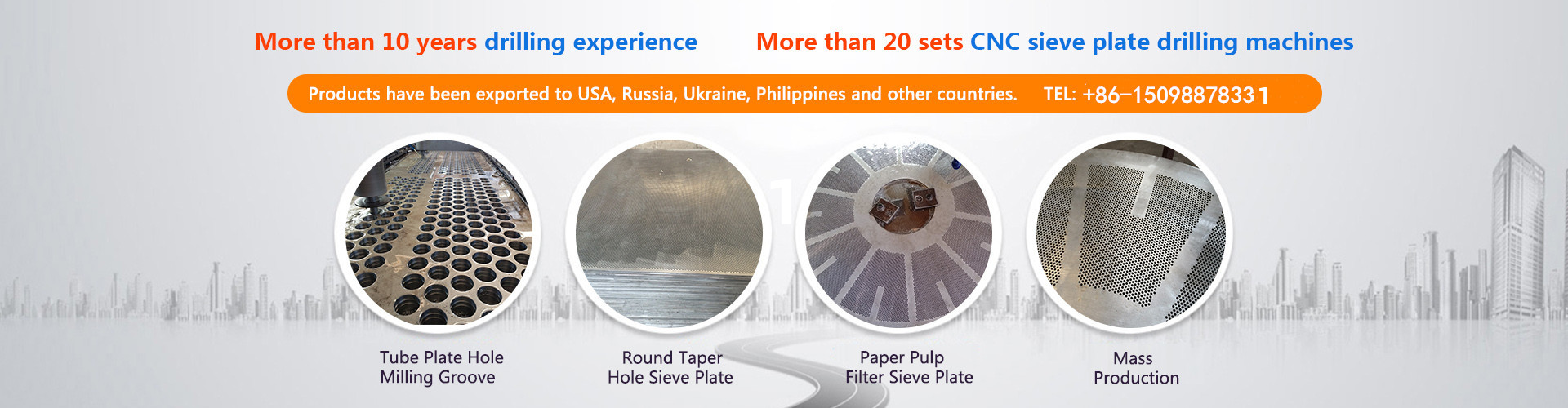

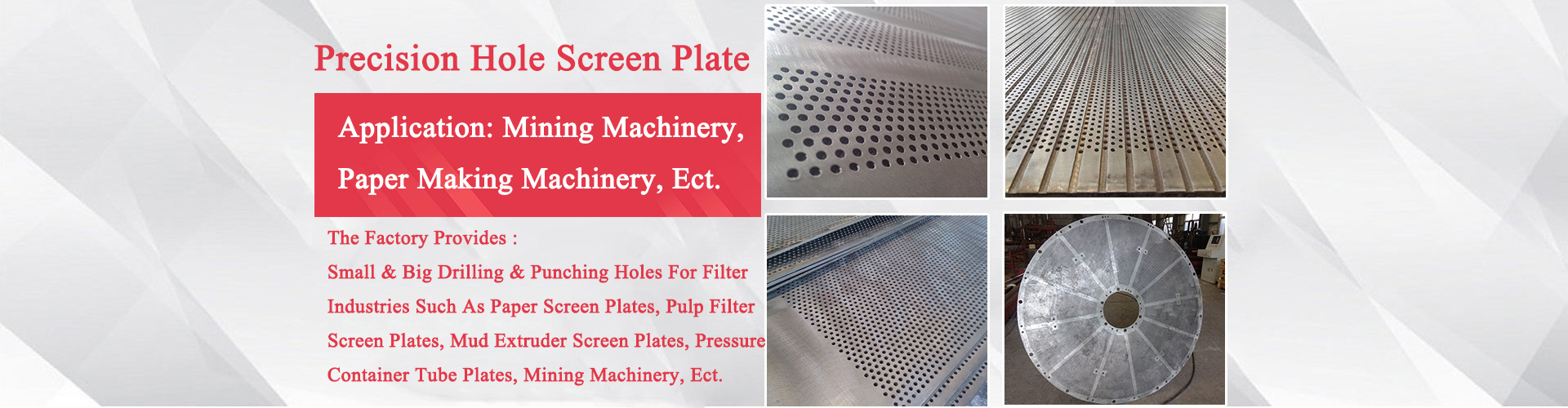

For the stainless steel sieve plate, it is a metal plate with evenly distributed mesh holes. During the use, the gap is inevitable. What we have to do is how to control. Let's take a concrete explanation:

The appearance of gaps in stainless steel screens is common and inevitable, and only the gaps can be minimized. The gap is mainly controlled by shear shear stress, and shear produces two forces, one is shear compressive stress and the other is shear tensile stress. When the crack is not easily generated under the shear compressive stress, the gap of the sieve plate becomes small. Conversely, the shear under tensile stress increases under shear tensile stress. The brighter the gap in the stainless steel sieve plate is the smaller factor.

The control of the gap during the stainless steel screen blanking process is critical, and at the same time the strength will not only affect the gap problem of the stainless steel screen, but also affect the overall flatness of the product and the welding and bending effects. Therefore, in order to better guarantee the technical problems of the products, it is necessary to select different strengths according to different situations to ensure the overall effect.

The appearance of gaps in stainless steel screens is common and inevitable, and only the gaps can be minimized. The gap is mainly controlled by shear shear stress, and shear produces two forces, one is shear compressive stress and the other is shear tensile stress. When the crack is not easily generated under the shear compressive stress, the gap of the sieve plate becomes small. Conversely, the shear under tensile stress increases under shear tensile stress. The brighter the gap in the stainless steel sieve plate is the smaller factor.

The control of the gap during the stainless steel screen blanking process is critical, and at the same time the strength will not only affect the gap problem of the stainless steel screen, but also affect the overall flatness of the product and the welding and bending effects. Therefore, in order to better guarantee the technical problems of the products, it is necessary to select different strengths according to different situations to ensure the overall effect.